Deep drilled barrels:

All FABARM barrels of 12, 20 and 28 calibre are produced by deep drilling technology out of solid steel bars of nickel chrome molybdenum. This technology, reserved by our competitors for the most prestigious, top-quality products, allows the molecular structure of the steel to remain intact during the manufacture of the barrels. The barrels, thus having none of the tension inevitably generated by the process of cold forging, remain perfectly rectilinear during the phase of silver soldering the components of the barrel (top rib, tenon, gas cylinder) at temperatures of over 700 degrees. The advantage of this production process – better steel elasticity, less recoil – added to the TRIBORE profile explain why FABARM guns offer probably today’s best ballistic results, as much in terms of distribution as for long-distance penetration.

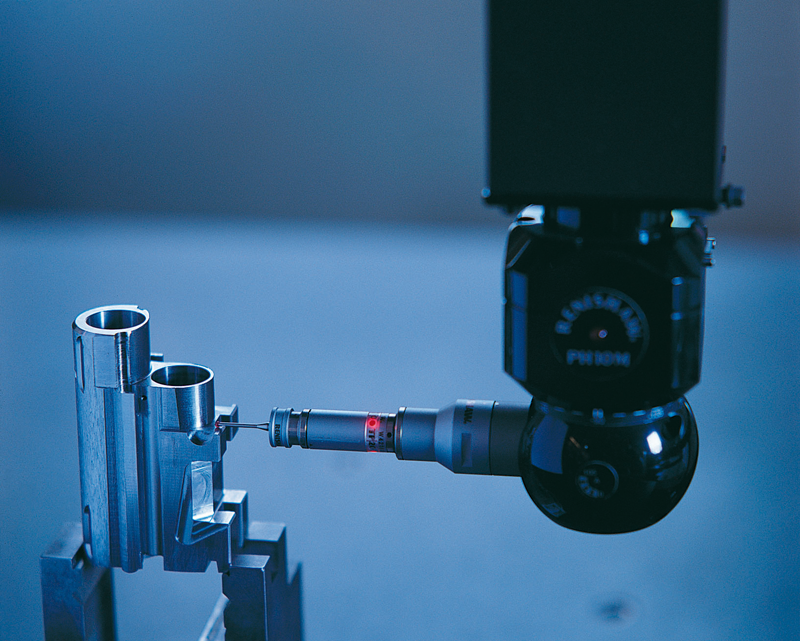

Metrology and sensory analysis.

Quality has been a daily priority for decades. Extremely modern production facilities and quality control systems represent major investments in the FABARM factory. To metrology is added a further sensory analysis of FABARM products with the notion of perceived quality. In this way, FABARM firearms use mostly surface finishes (TITANIUM™ treatment, SOFT TOUCH™ treatment, etc …) and care taken in the ergonomics of design, making them clearly the benchmarks of their sector over the last decade.